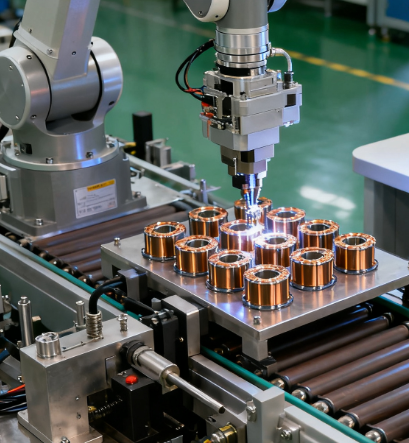

Filter cores are the backbone of EMI filters and chokes—they suppress unwanted electromagnetic noise, ensure electronic devices meet global EMC (Electromagnetic Compatibility) standards, and protect sensitive components from interference. Whether you’re producing consumer electronics, industrial equipment, or automotive electronics, the right filter core partner can make or break your product’s performance and market access. We’ve integrated three core strengths—ODM EMI filter core development, filter choke core supply, and OEM filter magnetic core production—to be your one-stop solution for all filter core needs.

1. As an ODM EMI Filter Core Factory: Custom Solutions for EMI Challenges

Every electronic device faces unique EMI challenges—from high-frequency noise in 5G devices to harsh industrial interference in factory equipment. Off-the-shelf EMI filter cores often can’t meet these specific needs, which is where our ODM EMI filter core factory expertise comes in:

- EMI-Specific ODM Development: We start by understanding your device’s operating environment, noise frequency range, and compliance requirements (such as CE, FCC, or CISPR). Our engineering team then designs EMI filter cores optimized for your use case—from material selection (high-permeability ferrite, nanocrystalline alloys for low-frequency noise, or amorphous alloys for high-frequency suppression) to core geometry (toroidal, drum, or custom shapes to fit tight device enclosures). We use EMI simulation tools to test core performance, refine designs to reduce noise by up to, and validate compliance before mass production.

- Industry-Focused ODM Solutions: We specialize in ODM EMI filter cores for key sectors:

- Consumer Electronics: Compact cores for smartphones, laptops, and smart home devices to meet strict EMC standards without adding bulk.

- Industrial Equipment: Rugged cores for factory automation tools and power supplies, resistant to vibration and temperature fluctuations.

- Automotive Electronics: High-temperature cores for in-vehicle infotainment and ADAS (Advanced Driver Assistance Systems), compliant with automotive EMC standards (ISO 11452).

- Fast ODM Turnaround: We understand that getting products to market quickly is key. Our ODM process—from design to prototype to production—takes as little as 4-6 weeks, compared to the industry average of 8-10 weeks. This speed helps you stay ahead of competitors and meet tight product launch deadlines.

Our ODM EMI filter cores have helped clients solve critical interference issues—from a 5G router brand reducing signal noise to an industrial equipment maker meeting strict EU EMC standards.

2. As a Filter Choke Core Supplier: Stable Supply for Reliable Chokes

Filter chokes are essential for power supplies, inverters, and industrial electronics—they smooth current flow and prevent noise from entering or leaving a system. The quality and consistency of choke cores directly impact choke performance, which is why we prioritize reliability as a Filter choke core supplier:

- Wide Range of Choke Core Options: We offer filter choke cores for all common choke types, including power chokes, common-mode chokes, and differential-mode chokes. Our product line covers standard sizes (from small 10mm-diameter cores for consumer electronics to large 100mm cores for industrial power supplies) and materials (ferrite, silicon steel, and sendust alloys) to match different current and frequency requirements.

- Consistent Quality for Choke Performance: Chokes rely on uniform magnetic properties across cores to ensure stable current smoothing. We use automated production lines and strict quality control—every filter choke core undergoes testing for permeability, saturation flux density, and dimensional accuracy. This consistency means your chokes perform reliably, with minimal variation between units.

- Flexible Supply & Fast Delivery: We maintain a large inventory of standard filter choke cores to support quick order fulfillment. For custom choke core needs (e.g., non-standard sizes or materials), we offer flexible production schedules to align with your choke manufacturing timeline. We also support long-term supply agreements to ensure you never face stockouts during peak production.

3. As an OEM Filter Magnetic Core Manufacturer: Brand-Aligned Production

For electronics brands that need filter cores matching their specific design, packaging, or quality standards, our OEM filter magnetic core manufacturer services deliver seamless integration with your brand:

- Full-Brand Customization: We align with your brand’s requirements at every step—from core labeling (printing your logo or part numbers) to packaging (using your branded boxes or trays to fit your assembly line workflow). We also adapt to your quality standards, whether you require additional testing (such as thermal shock or humidity resistance) or compliance with industry-specific certifications (like UL for North America or VDE for Europe).

- Adapt to Production Needs: We support OEM orders of all sizes—from small batches (500 units) for product testing to large-volume orders (10,000+ units) for mass production. We also offer flexible lead times, adjusting our production schedule to match your manufacturing cycles and avoid overstocking.

- Technical Collaboration: Our team provides technical support to help your engineering team integrate OEM filter cores into your devices. We share core specifications, recommend winding guidelines for chokes/filters, and assist with troubleshooting any integration issues—saving you time and reducing production errors.

Our OEM filter magnetic cores have been used in branded electronics worldwide—from a leading laptop maker’s power supplies to a smart TV brand’s EMI suppression systems.

Why Choose Us for Your Filter Core Needs?

- One-Stop Expertise: We combine ODM innovation, filter choke core supply, and OEM customization—no need to work with multiple suppliers, simplifying your sourcing process.

- Compliance & Quality: All our filter cores meet global standards (IEC, EMC, UL, VDE) and undergo rigorous testing. We hold ISO 9001 and ISO 14001 certifications, ensuring consistent quality and environmentally friendly production.

- Global Support: We serve clients in 30+ countries, with multilingual support (English, Spanish, German, Mandarin) and flexible shipping options (DHL, FedEx, sea freight). Our after-sales team is available 24/7 to address any issues, ensuring a smooth partnership.

If you’re looking for a specialized ODM EMI filter core factory, reliable Filter choke core supplier, or experienced OEM filter magnetic core manufacturer, contact us today. We’ll share case studies relevant to your industry, provide a personalized quote, and help you solve your filter core challenges.