In the rapidly evolving world of electrical engineering and power systems, finding a reliable ODM amorphous C-core manufacturer is crucial for businesses seeking high-performance components. These manufacturers specialize in producing amorphous C-cores, which are essential for transformers and inductors due to their superior magnetic properties and energy efficiency. As industries push towards more sustainable and efficient solutions, partnering with an experienced ODM amorphous C-core manufacturer can provide customized solutions that meet specific application needs.

Understanding Amorphous C-Cores

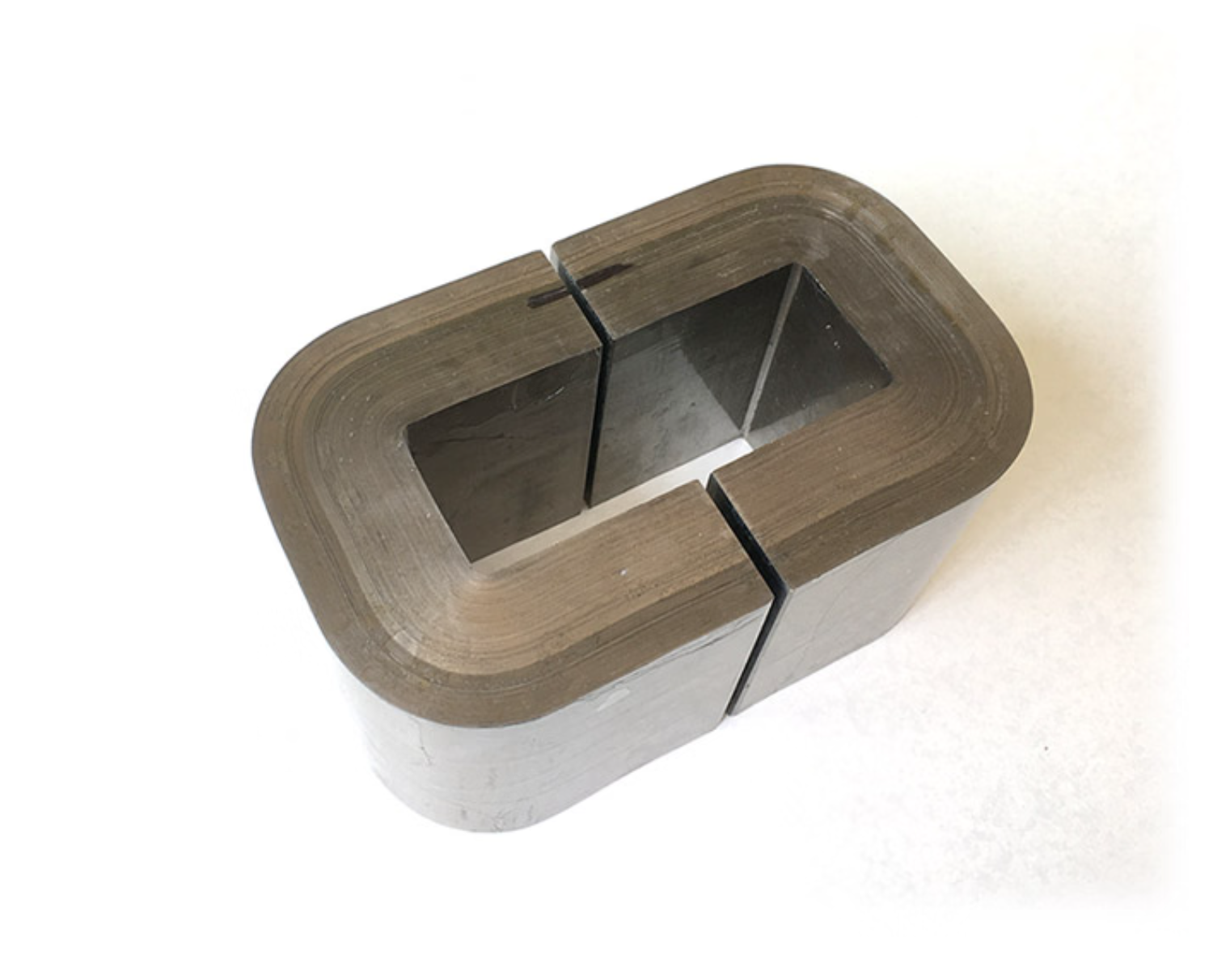

Amorphous C-cores are made from amorphous metal alloys, which exhibit unique properties such as low core loss and high permeability. Unlike traditional silicon steel cores, amorphous materials reduce energy wastage significantly, making them ideal for modern power distribution systems. An ODM amorphous C-core manufacturer employs advanced techniques to form these cores into a C-shape, which allows for easy assembly and disassembly in transformer designs. This shape also minimizes magnetic flux leakage, enhancing overall efficiency. Businesses looking for an amorphous cut core supplier will find that these components are versatile, used in everything from renewable energy systems to consumer electronics.

The production process involves rapid solidification of molten metal to create the amorphous structure, which prevents the formation of crystalline grains that cause energy losses in conventional materials. As a leading ODM amorphous C-core manufacturer, the focus is on precision engineering to ensure each core meets stringent quality standards. This results in products that offer reduced noise, lower operating temperatures, and longer lifespans, contributing to more reliable electrical systems.

Benefits of Choosing an ODM Approach

Opting for an ODM amorphous C-core manufacturer means gaining access to original design manufacturing services, where the manufacturer handles everything from design to production. This is particularly beneficial for companies without in-house R&D capabilities, allowing them to bring innovative products to market faster. An amorphous cut core supplier in this model can customize cores to specific dimensions, winding configurations, and performance requirements, ensuring optimal integration into various applications.

One key advantage is cost-effectiveness; by leveraging the manufacturer's expertise and economies of scale, businesses can reduce development costs and time. Moreover, ODM services often include prototyping and testing, which help in refining the product before full-scale production. For industries like automotive, telecommunications, and renewable energy, where efficiency is paramount, an ODM amorphous C-core manufacturer provides components that support greener technologies by minimizing energy consumption.

Applications in Modern Industries

Amorphous C-cores are pivotal in high-frequency transformers, where their low loss characteristics shine. In solar inverters and wind power systems, these cores help convert and manage power with minimal waste. An amorphous cut core supplier ensures that these components are available in various sizes and specifications to fit diverse needs. Additionally, in electric vehicles, amorphous C-cores contribute to lighter, more efficient charging systems, supporting the shift towards sustainable transportation.

In the realm of industrial automation, these cores are used in inductors and chokes to filter noise and stabilize currents. The durability of amorphous materials makes them suitable for harsh environments, such as those in aerospace or marine applications. By choosing a reputable ODM amorphous C-core manufacturer, companies can ensure compliance with international standards like ISO and RoHS, guaranteeing safety and environmental responsibility.

Why Partner with a Trusted Supplier

Selecting the right amorphous cut core supplier involves evaluating factors like material quality, production capacity, and customer support. A top-tier ODM amorphous C-core manufacturer offers not just products but comprehensive solutions, including technical consultation and after-sales service. This partnership fosters innovation, as manufacturers often collaborate on R&D to develop next-generation cores with even better performance metrics.

In today's competitive market, reliability is key. An experienced amorphous cut core supplier can provide consistent quality, helping businesses avoid downtime and maintain operational efficiency. With global supply chains becoming more complex, having a dependable ODM amorphous C-core manufacturer ensures timely delivery and scalability to meet growing demands.

Future Trends and Innovations

The future of amorphous C-cores looks promising with ongoing advancements in material science. Researchers are exploring ways to enhance the magnetic properties further, potentially leading to even lower losses and higher saturation points. An ODM amorphous C-core manufacturer at the forefront of these innovations can offer cutting-edge products that keep pace with technological progress.

As the world moves towards electrification and smart grids, the demand for efficient magnetic components will surge. Partnering with a versatile amorphous cut core supplier positions businesses to capitalize on these trends, driving efficiency and sustainability. In conclusion, whether you're in power electronics or renewable energy, investing in high-quality amorphous C-cores from a trusted ODM amorphous C-core manufacturer is a strategic move towards a more efficient future.