Introduction

As the world transitions towards sustainable energy and electrification, the demand for components that maximize efficiency and minimize losses has never been greater. Among these, the amorphous core stands out as a key enabler of next-generation transformers and inductors.

Unlike traditional silicon steel, amorphous alloys are produced through rapid solidification, creating a non-crystalline atomic structure that significantly reduces hysteresis and eddy current losses. The result: transformers that consume less energy, run cooler, and last longer.

For businesses across the power, automotive, and renewable sectors, choosing the right amorphous core supplier can mean the difference between outdated technology and competitive, future-proof solutions.

Understanding Amorphous Cores

Amorphous metal alloys are created by cooling molten metal at an extremely fast rate, preventing the formation of a crystalline grain structure. This unique composition gives them exceptional properties:

-

Ultra-Low Core Losses: Typically 70% lower than silicon steel cores.

-

High Permeability: Better magnetic response for high-frequency applications.

-

Reduced Noise: Lower magnetostriction means quieter operation.

-

Thermal Stability: Operates efficiently at a wide temperature range.

Because of these advantages, amorphous cores are increasingly replacing traditional materials in industries demanding energy efficiency and environmental compliance.

Why Partner with a Professional Amorphous Core Supplier?

1. Customization

A reliable supplier offers tailored solutions—cut cores, C-cores, and toroidal shapes—engineered to fit transformers, inductors, and custom applications.

2. OEM/ODM Services

Amorphous core suppliers often provide design, prototyping, and full-scale production. This shortens time-to-market and reduces R&D costs for clients.

3. Global Standards Compliance

Trusted suppliers follow ISO, IEC, and RoHS standards, ensuring products meet international requirements for safety and sustainability.

4. Cost Efficiency

Despite higher material complexity, large-scale suppliers optimize production to deliver cost-effective solutions without compromising performance.

5. Technical Support

Beyond supplying products, top suppliers provide engineering consultation, testing, and after-sales services to guarantee long-term reliability.

Applications of Amorphous Cores

Amorphous cores are versatile and widely adopted across industries:

-

Power Distribution Transformers: Reduce energy losses in smart grids and urban infrastructure.

-

Renewable Energy: Enhance efficiency in wind turbine generators and solar inverters.

-

Electric Vehicles (EVs): Improve charging efficiency and reduce energy waste in onboard chargers.

-

High-Frequency Transformers: Provide stable operation for telecommunications and data centers.

-

Industrial Automation: Used in chokes and inductors for noise filtering and stable current flow.

By integrating amorphous cores, companies can significantly cut operating costs while meeting stricter environmental regulations.

Manufacturing Process of Amorphous Cores

-

Rapid Solidification: Molten alloy is cooled rapidly into thin ribbons.

-

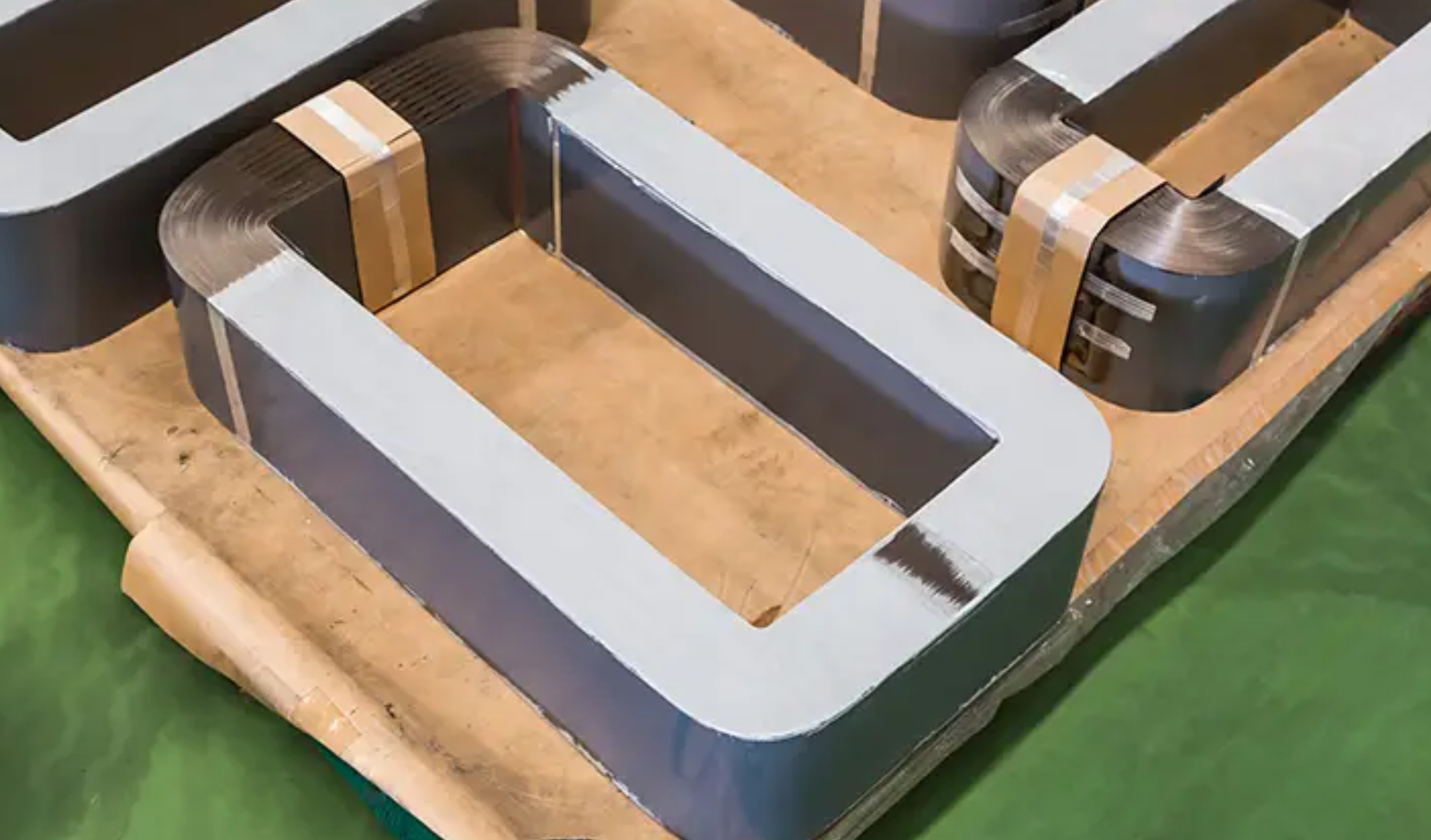

Cutting & Shaping: Ribbons are formed into desired core shapes (toroidal, C-core, or custom).

-

Annealing: Heat treatment optimizes magnetic properties while relieving internal stresses.

-

Assembly: Laminations or ribbons are stacked or wound to create the final core.

-

Testing: Suppliers perform loss measurement, permeability checks, and dimensional inspection.

Every step requires precision, making supplier expertise a critical factor in performance and reliability.

Future Trends in Amorphous Core Industry

-

Green Energy Integration: With global pressure to reduce CO₂ emissions, amorphous cores will dominate transformer markets in renewable energy systems.

-

EV Expansion: Electric vehicles will demand compact, high-efficiency cores for fast charging.

-

Smart Grids: Amorphous cores will power transformers designed for dynamic, real-time grid management.

-

Hybrid Materials: Combination of amorphous and nanocrystalline materials to achieve even lower losses and higher magnetic performance.

How to Choose the Right Amorphous Core Supplier

When selecting a supplier, businesses should evaluate:

-

Proven track record in transformer and inductor applications

-

OEM/ODM customization capability

-

Compliance with ISO and RoHS standards

-

Production scalability for both small and large orders

-

Technical consultation and after-sales support

A reliable supplier is not just a manufacturer but a long-term partner in innovation and sustainability.

Conclusion

Amorphous cores are revolutionizing the way transformers and power electronics operate. By drastically reducing losses, lowering operating costs, and enabling greener energy solutions, they are essential for the future of electrical engineering.

For industries seeking to stay competitive in a rapidly evolving energy landscape, partnering with a trusted amorphous core supplier ensures access to cutting-edge technology, reliable quality, and customized solutions.

As renewable energy and electrification trends accelerate, the role of amorphous cores—and their suppliers—will only grow more critical.